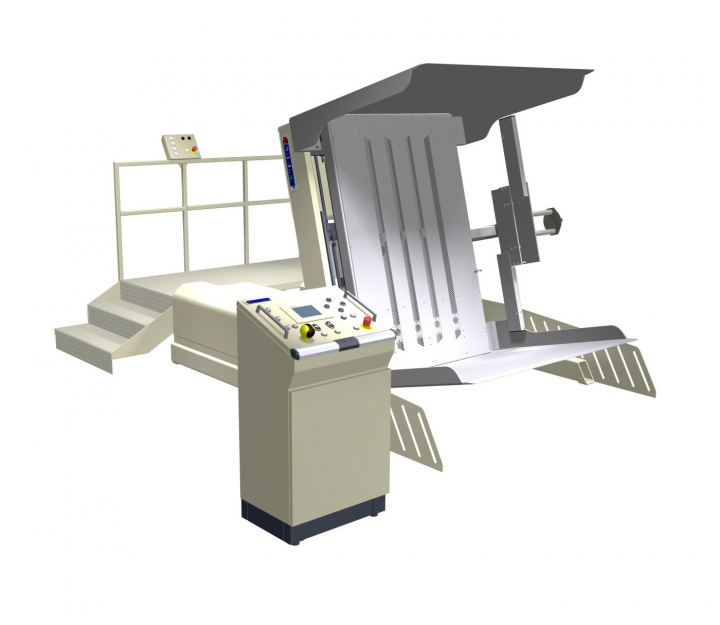

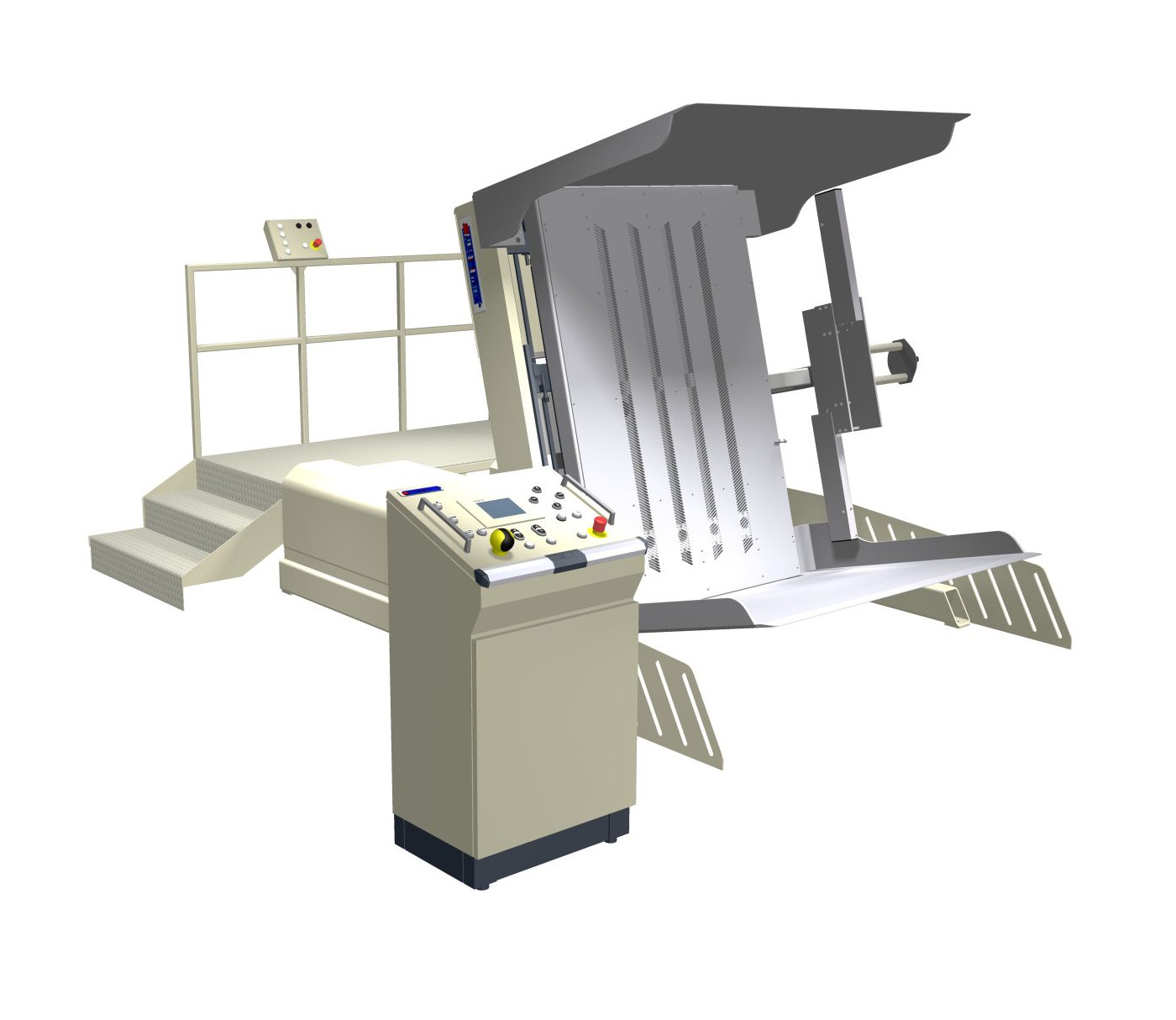

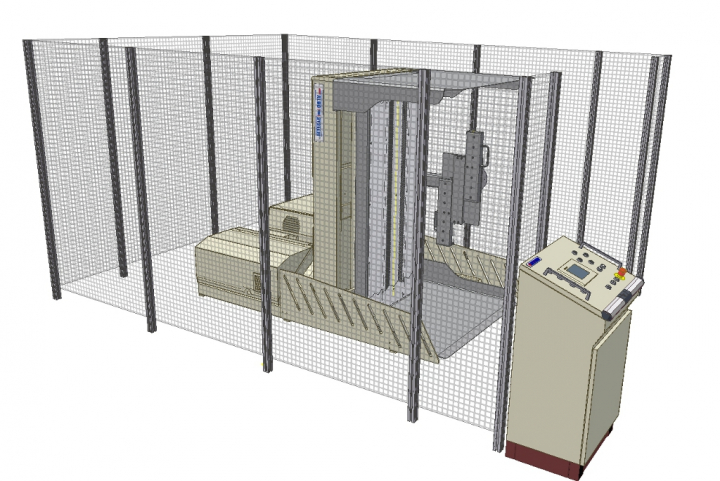

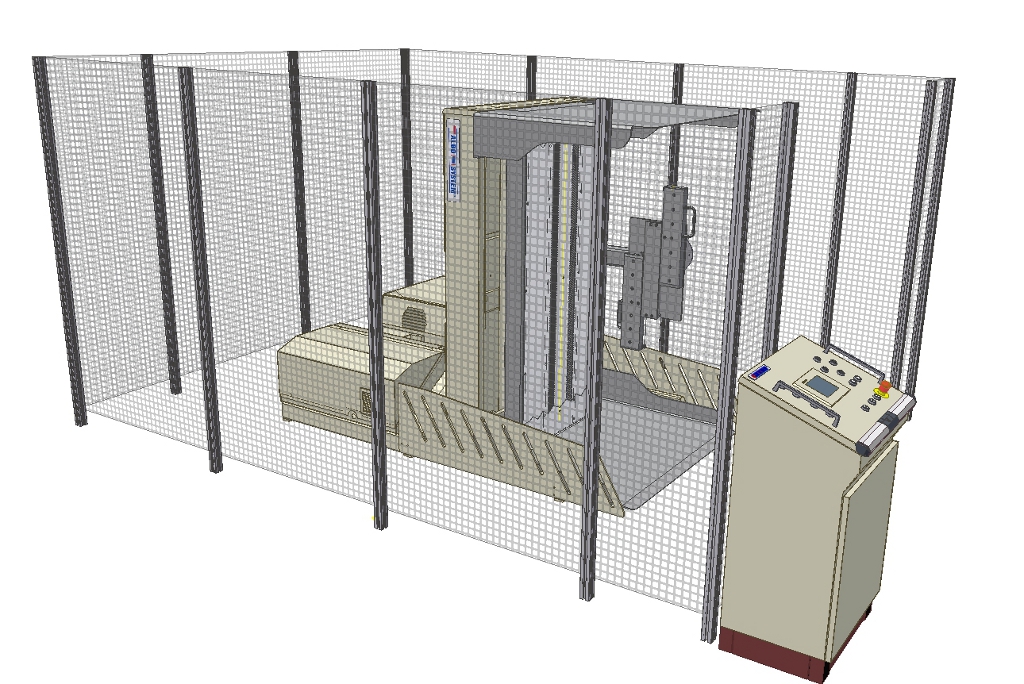

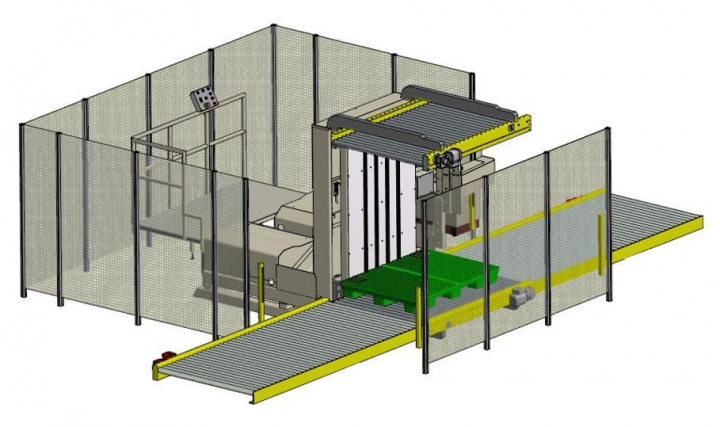

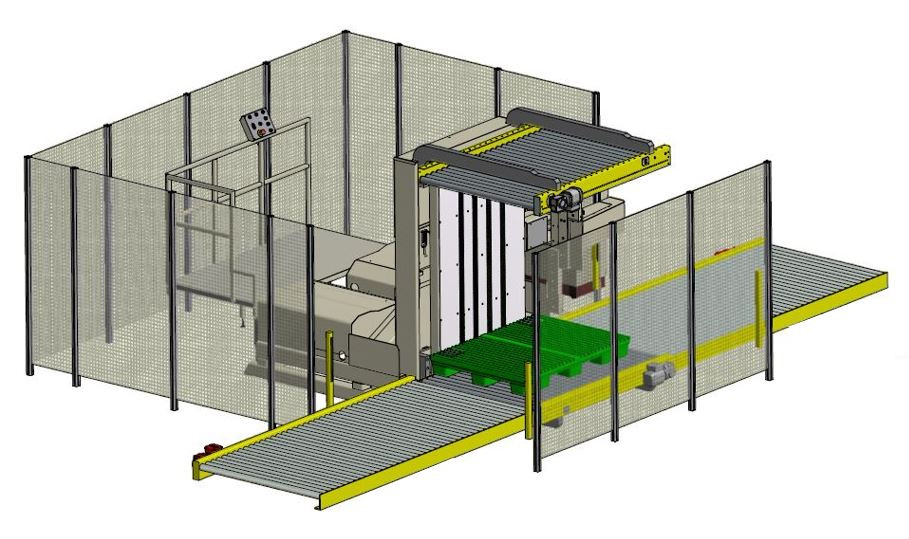

The Fully Automatic Pile Turners may also be installed in automatic production lines and integrated in-line with conveyor systems.

Typical applications are for die-cutter lines in the folding carton and corrugated board industries, and in packaging lines at paper mills.

Contact Albo System for more information.